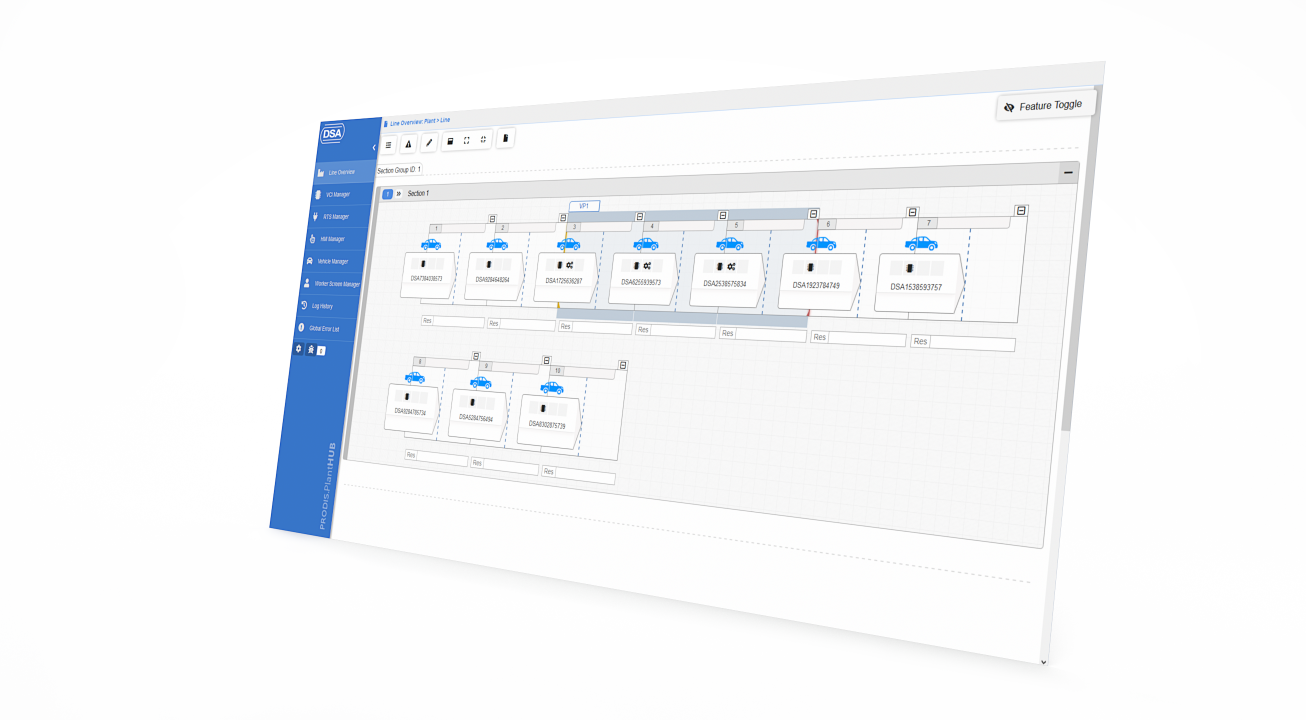

PRODIS.PlantHUB: The control logic at the heart of the round robin test system ensures that the right components are connected and tasks are performed in a variety of hybrid operating scenarios, including conventional diagnostic testers, smart and lean edges, and in-vehicle edges.

The Smart Diagnostic Grid not only improves the testing efficiency of automotive production, but also brings about a new change in the entire production process in terms of intelligence and efficiency.

Various integration methods

DSA circulating adapters:Utilizing WiFi technology to easily integrate vehicles into existing plant IT systems.

Lean Diagnostics Edge approach:With solutions such as the DSA WDI-2X, vehicles are connected via Wi-Fi to the relevant hardware computers or virtual testers on the production line to perform test sequences.

Smart Diagnostics Edge:Cycle testers with integrated test sequence execution (e.g. DSA smartMDI) for more efficient test processes.

For vehicles equipped with the DSA Connected Vehicle - Onboard Diagnostics software stack (core components include PRODIS.PDU and PRODIS.MCD), Edge Diagnostics allows test sequences to be performed both inside and outside the vehicle.

Users can interact intuitively via large fixed displays or portable devices (e.g. RCU-3, smart glasses, etc.) to enhance ease of operation.

Flexible and efficient commissioning management

Automatically executes commissioning scopes based on vehicle location and status for optimal resource allocation.

The central GUI displays the location and status of all vehicles and resources in real time, facilitating continuous monitoring of the vehicle production process throughout the assembly plant.

The dynamic connection between the diagnostic interface and the human-machine interface simplifies commissioning activities, reduces the burden on workers and improves work efficiency.

solutions@dsa.com.cn